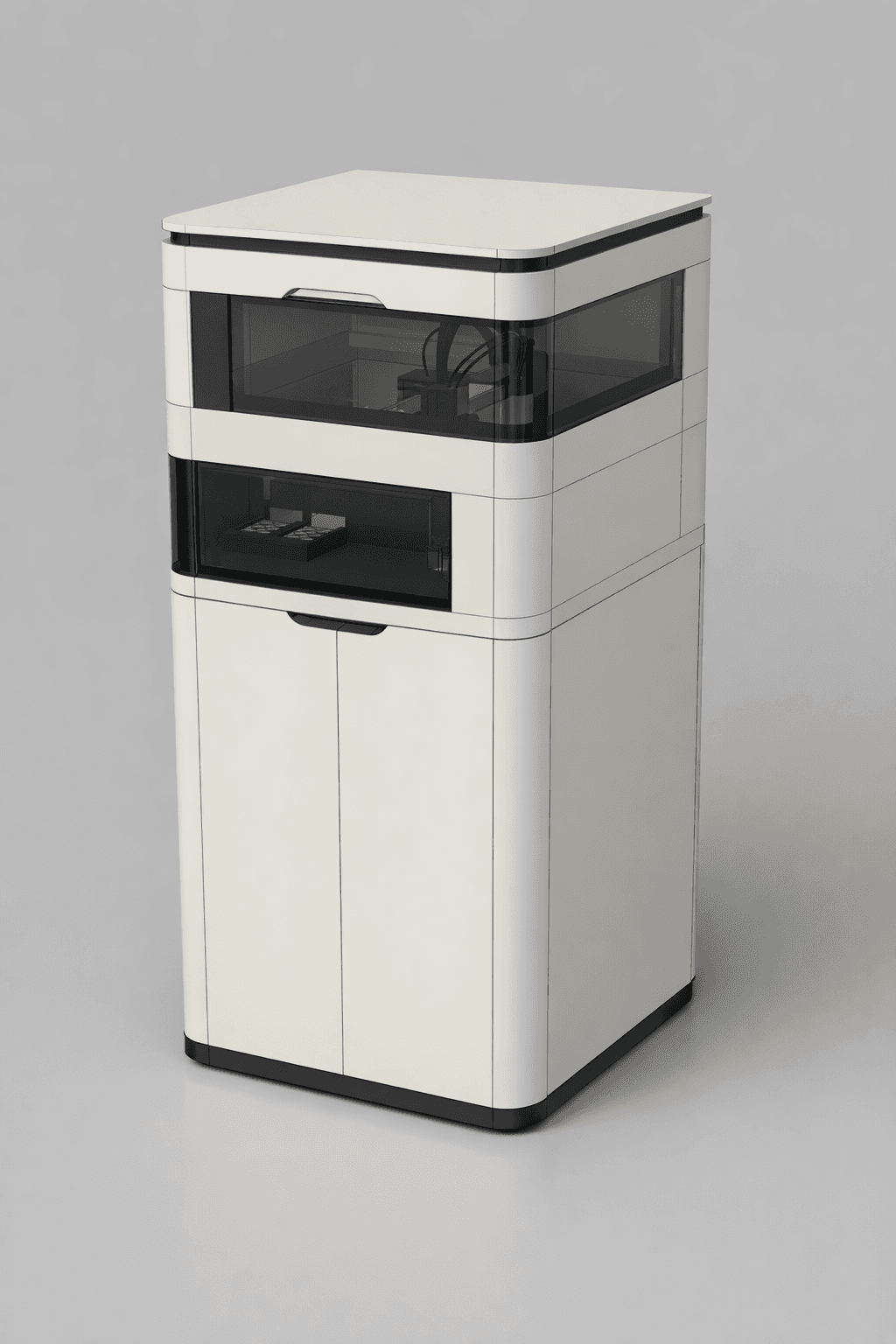

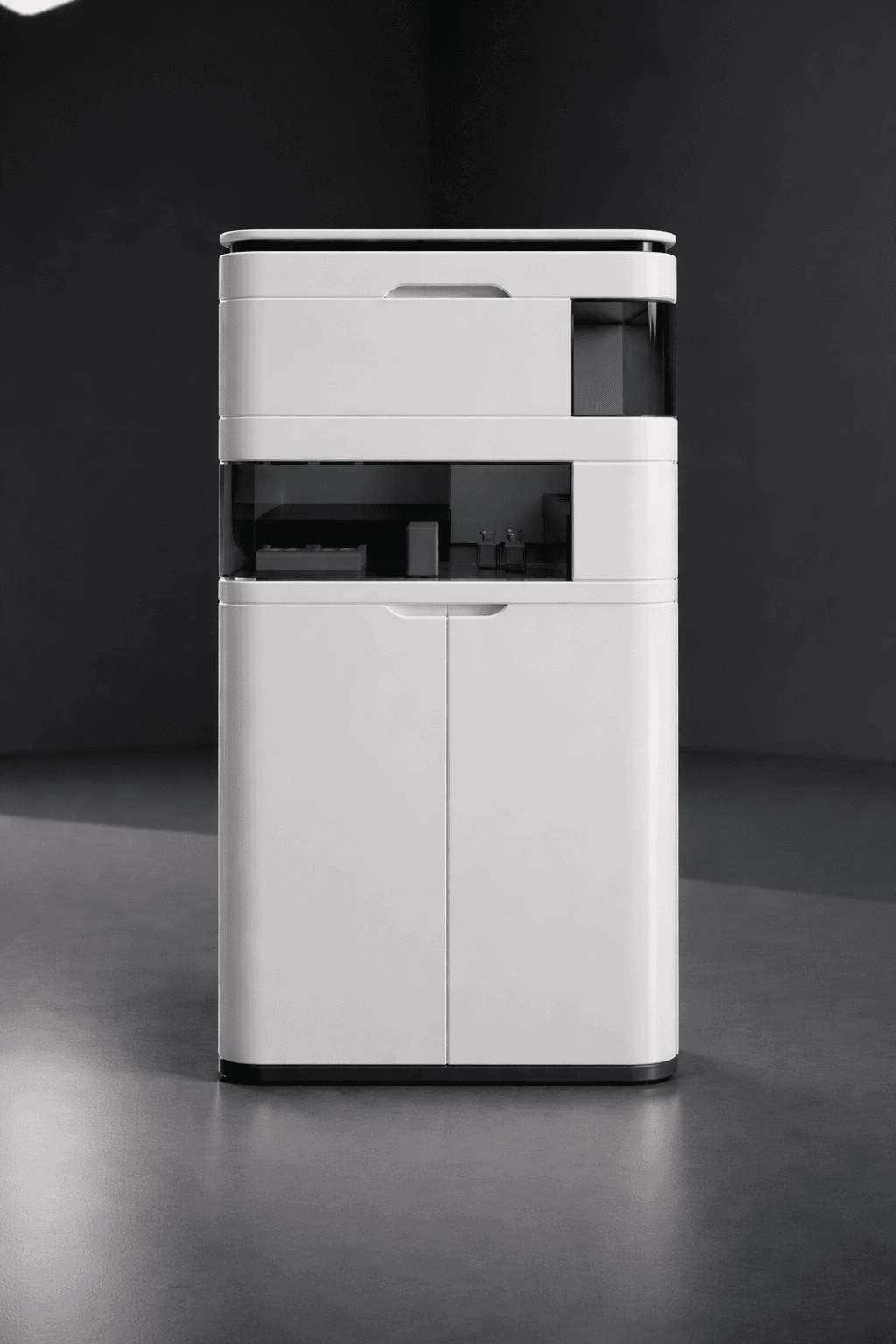

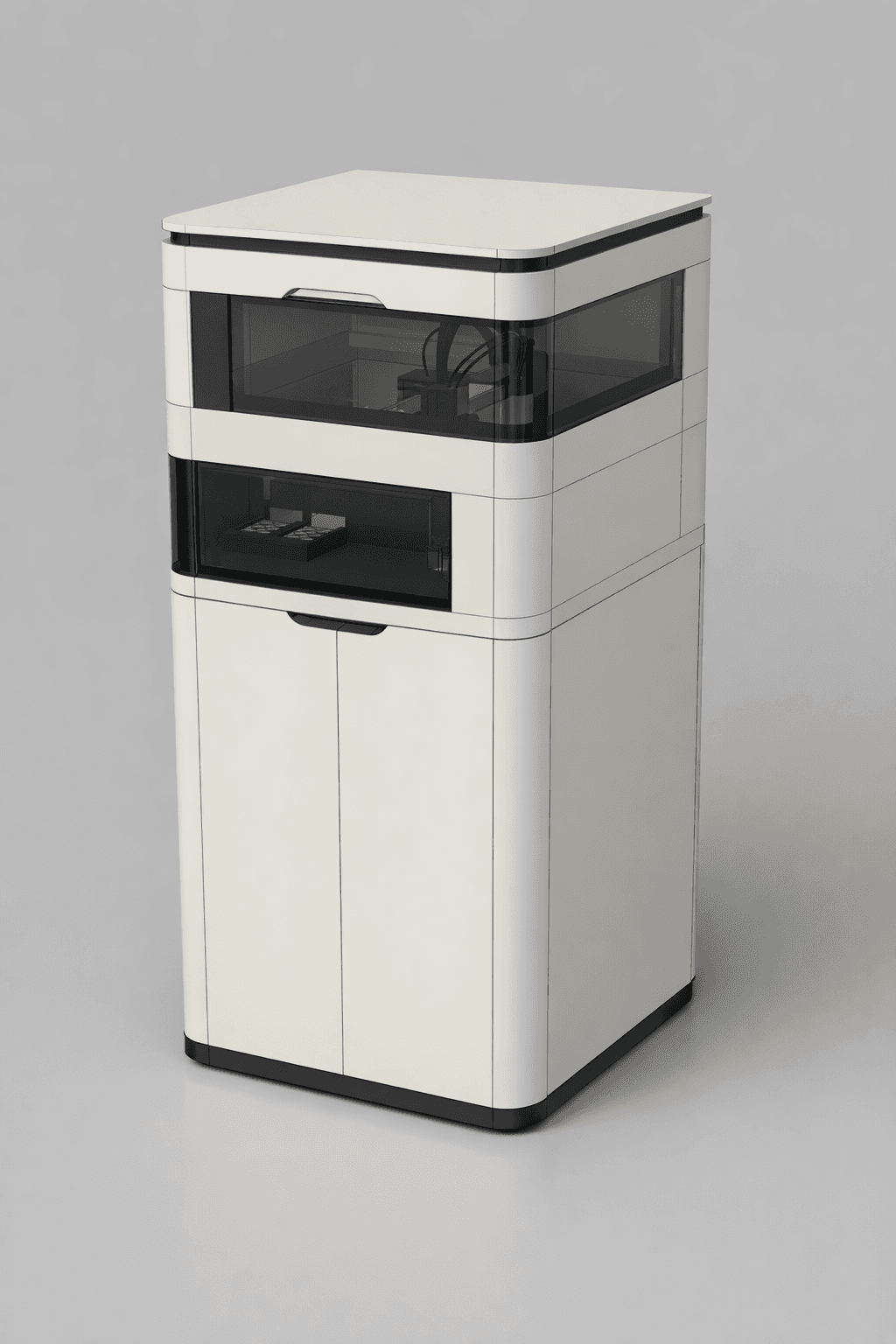

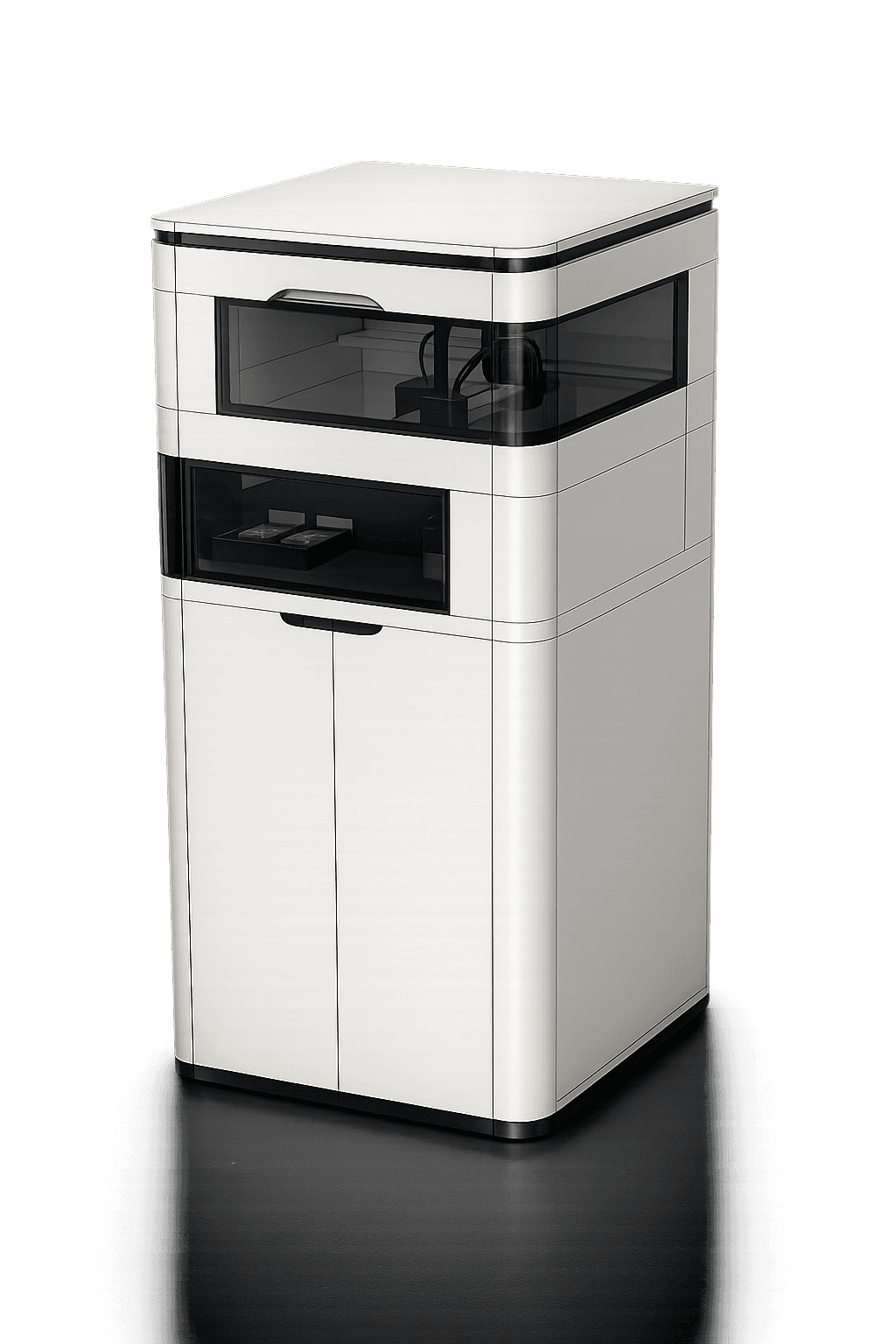

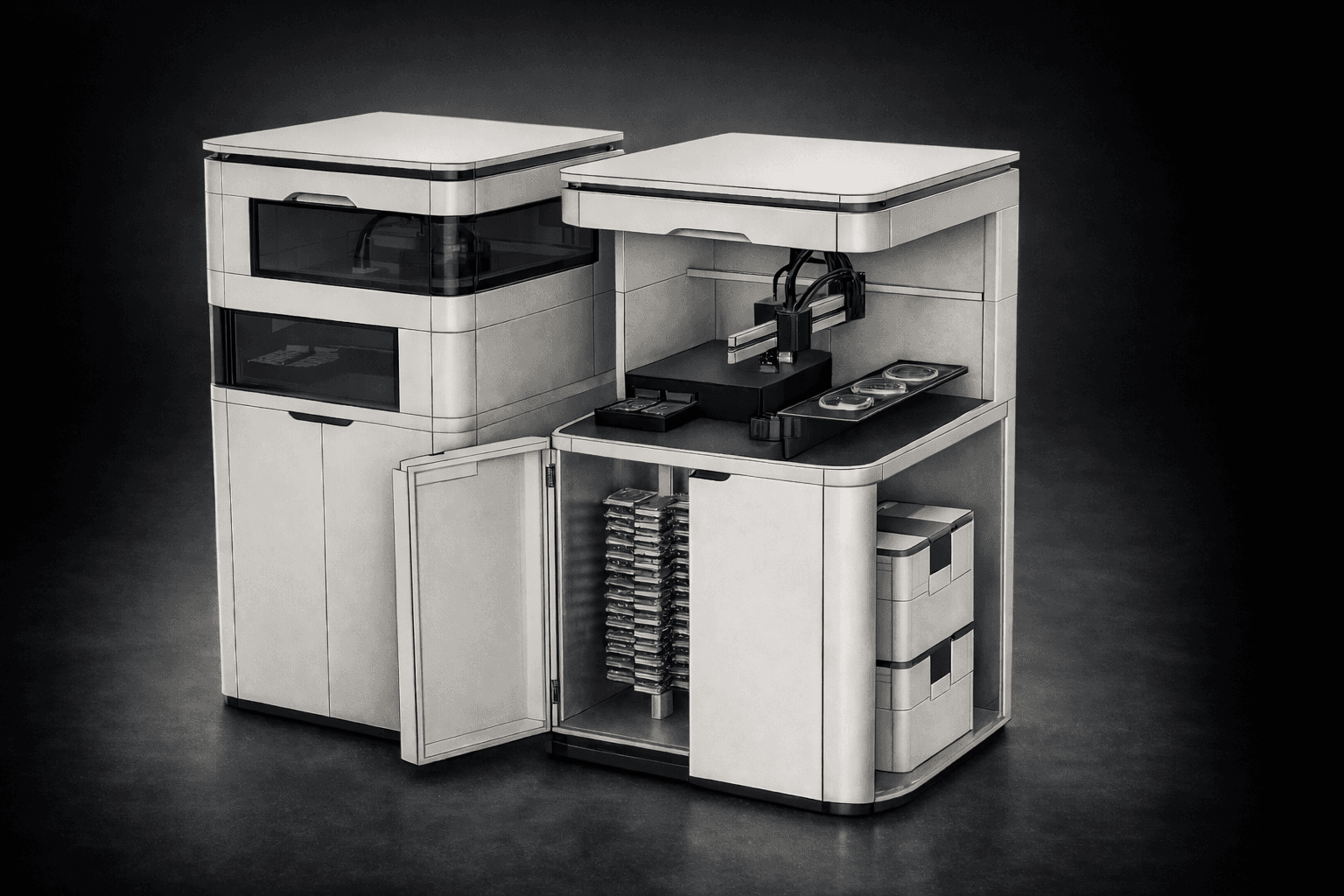

dALI 500

Manufacturing-scale automation for adherent SBS plate workflows. dALI 500 runs the same protocol logic used on dALI 24 at up to 500-plate throughput, with traceable execution across incubation, imaging, and liquid handling.

Scale a validated protocol, not a new process

dALI 500 is the manufacturing-scale extension of the dALI workflow model for high-throughput adherent SBS plate workflows. It executes the same protocol model as dALI 24 (schedules and decision rules), but at manufacturing throughput. Imaging and environmental context are recorded alongside every action to support comparability, deviation review, and process understanding.

- Up to 500 SBS plate throughput using the same workflow definitions as dALI 24

- Closed-loop operation: measured state (imaging + environment) can trigger protocol actions

- Compact 1 m × 1 m footprint for space-efficient deployment

The dALI 24 workflows, at production scale

dALI 500 is designed to run long-horizon, plate-based cell workflows with consistent timing and complete context. It is not just “more plates”; it is a scale-up path that preserves protocol intent and data structure from R&D validation.

Protocol portability

dALI 24 → dALI 500

Long-horizon runs

weeks, not hours

Up to 500 plates

throughput

Deterministic timing

less drift

Manufacturing intent

- Run the same protocol steps at higher throughput without rewriting workflows

- Batch-style execution with consistent scheduling across up to 500 plates

- In-process imaging checkpoints for drift and anomaly review

Space efficiency

- 1 m × 1 m footprint to maximise plates per square metre

- Designed for dense deployment: more capacity without a larger cleanroom

- Single integrated system reduces “many boxes” infrastructure sprawl

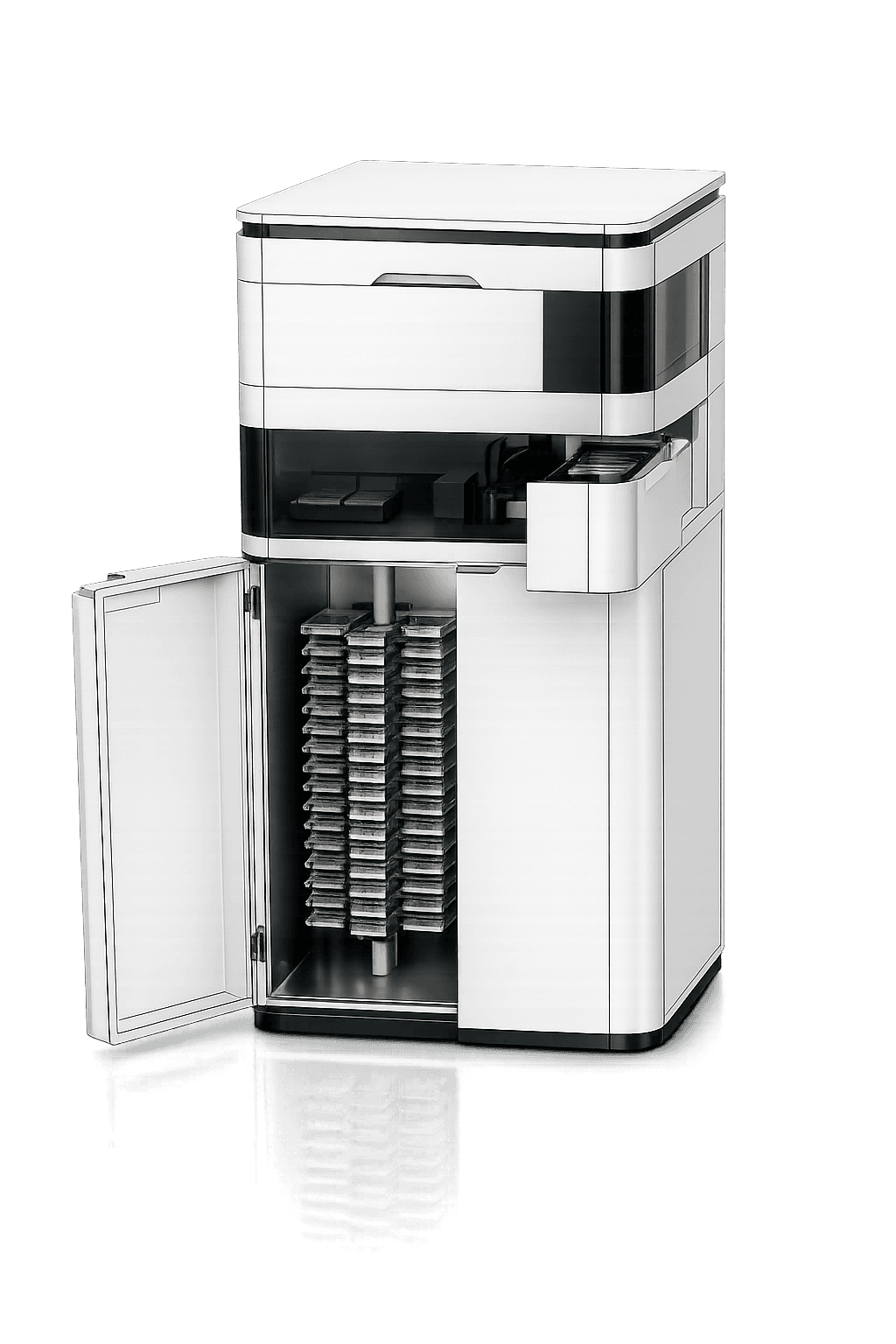

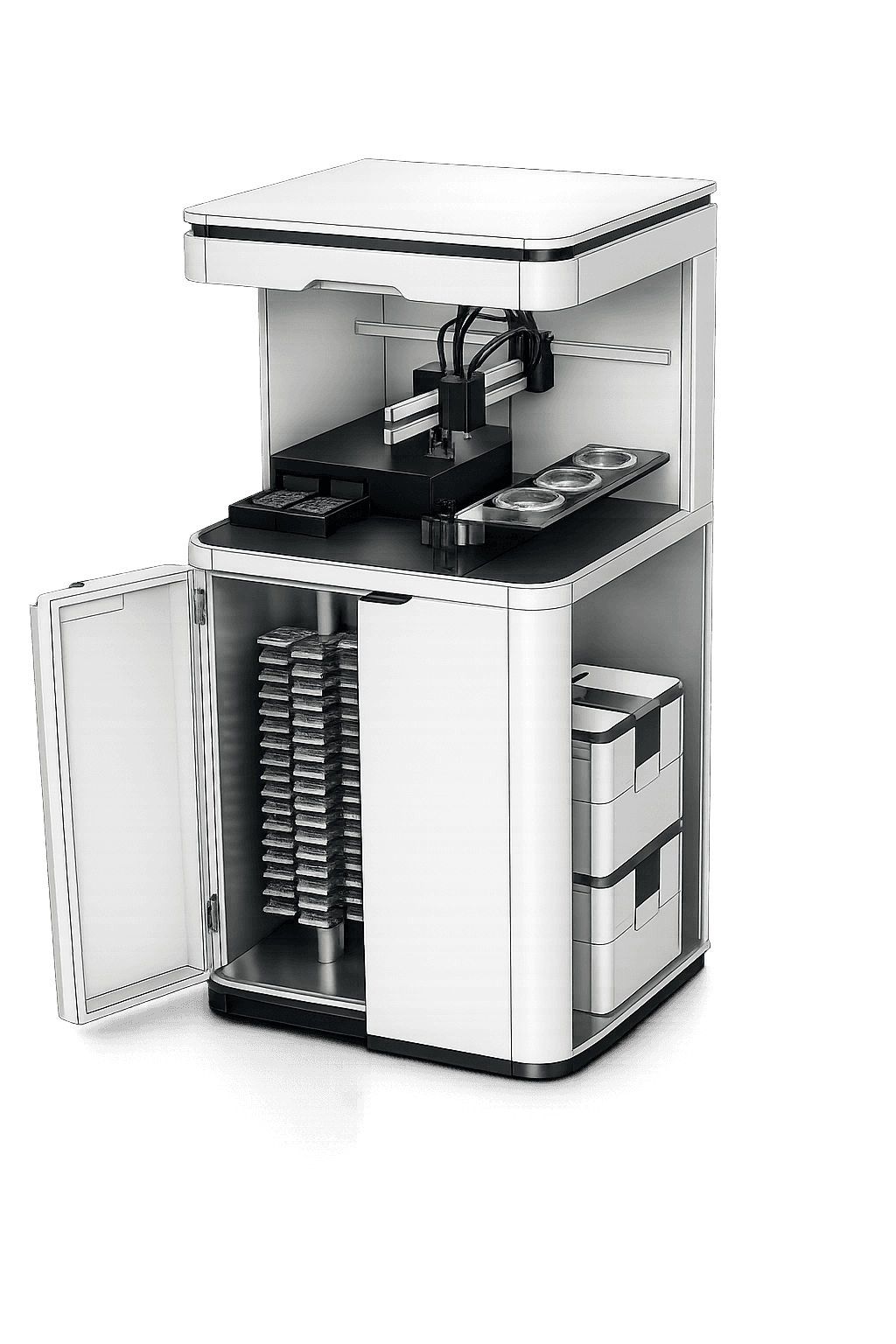

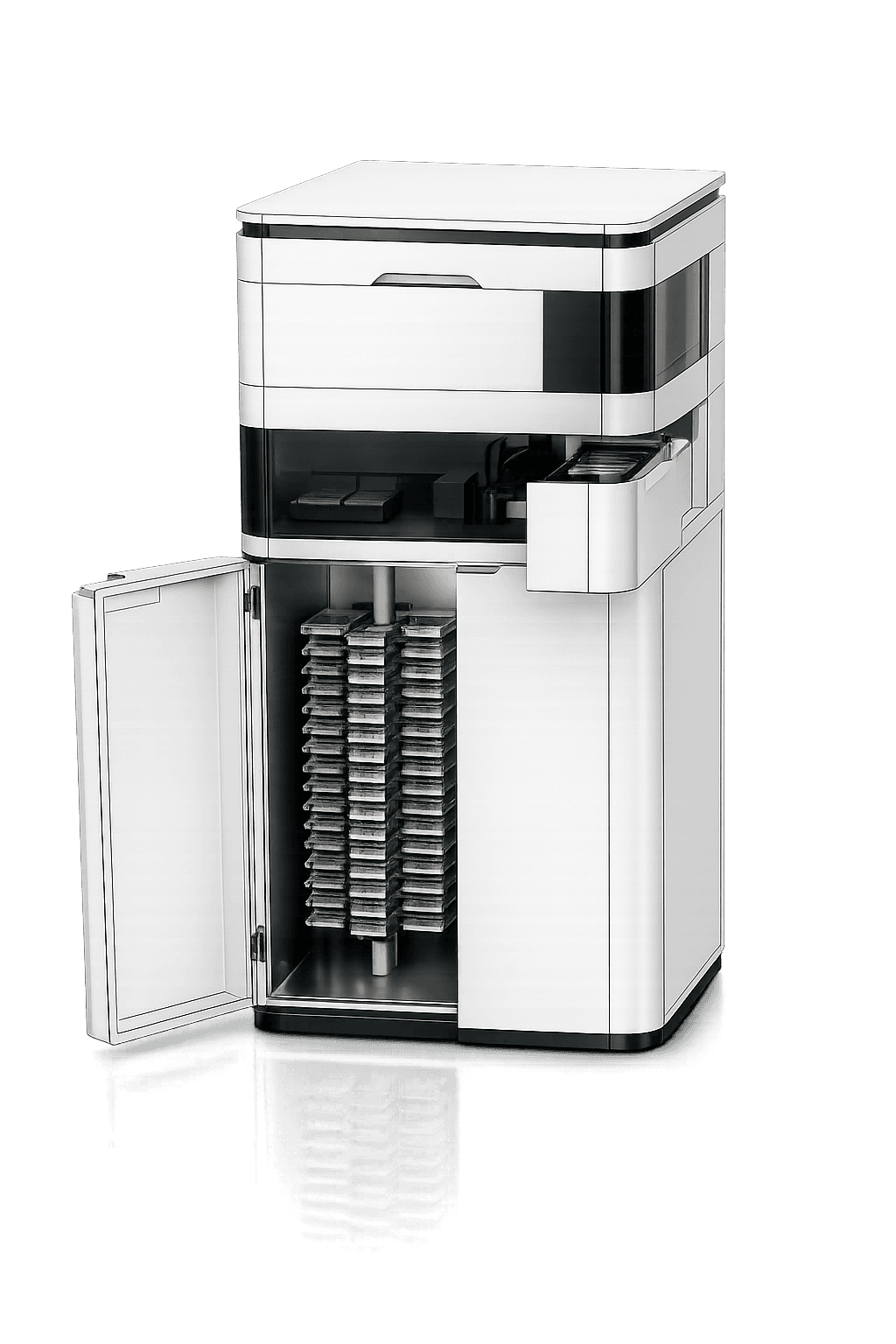

Integrated modules, single data model

dALI 500 combines incubation, plate movement, liquid handling, and imaging under one orchestration layer. Every action is timestamped and linked to protocol state, environmental context, and imaging checkpoints.

Incubation

Temperature control with CO₂ and O₂ setpoints, designed for stable long-horizon runs. Conditions are logged and time-aligned to protocol steps.

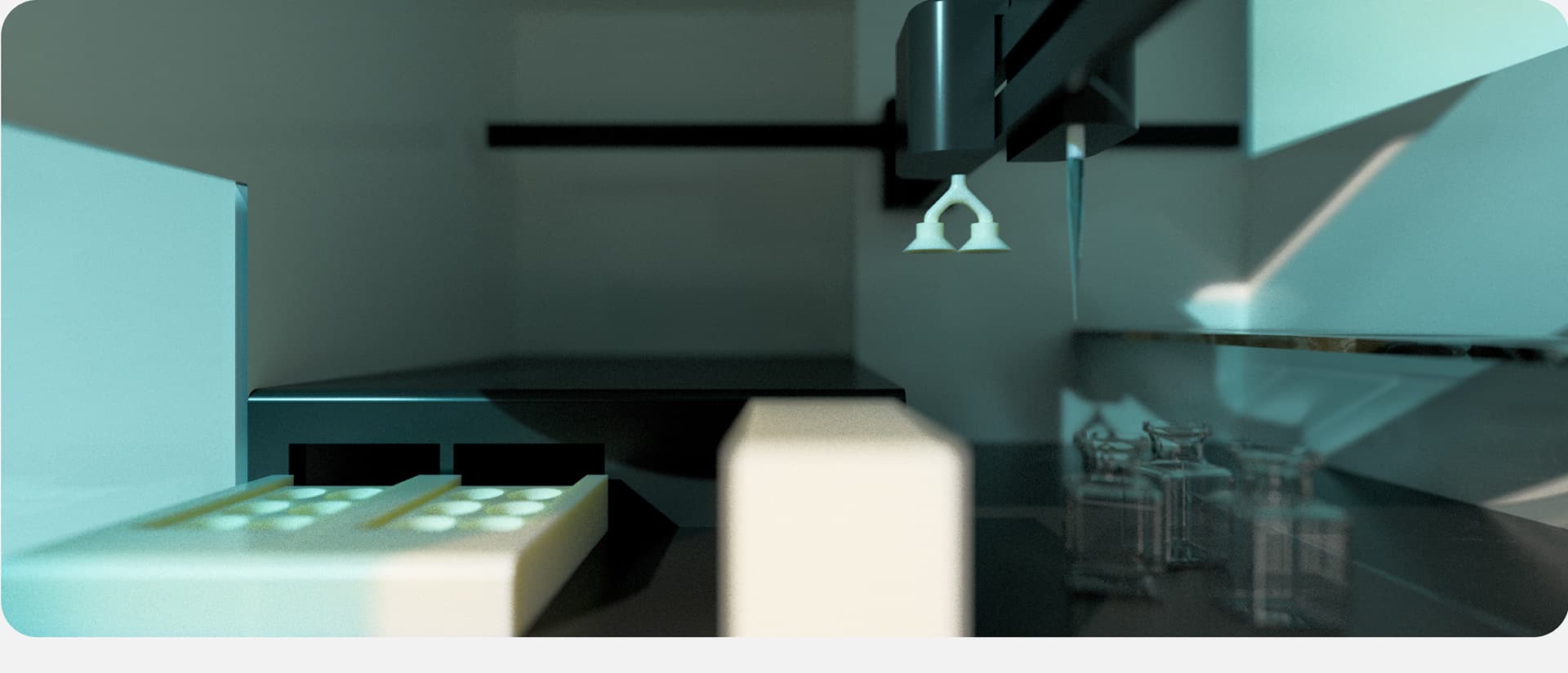

Liquid handling

High-throughput execution of media changes, dosing, washes, and passaging sequences. Steps are recorded as part of the batch record.

Imaging checkpoints

In-process imaging for QC and comparability. Capture consistent timepoints and link images directly to plate, well, time, and protocol state.

Plate handling

Automated plate movement with chain-of-custody logging. Designed to maintain deterministic timing across large plate volumes.

Complete system visualization

R&D → manufacturing with the same workflow definition

Develop and iterate protocols on dALI 24. When the workflow is stable, deploy the same protocol definition on dALI 500 to increase throughput while preserving timing, data structure, and QC checkpoints.

Protocol development

Define schedules and decision rules, then validate with imaging checkpoints and environmental logs.

- Workflow definition

- QC criteria and checkpoints

- Comparability across runs

Scale-out validation

Confirm the workflow behaves the same during scale-out: timing, handling, and QC metrics remain consistent.

- Scale-out studies

- Deviation review pathways

- Process understanding

Manufacturing throughput

Run the same protocol definition at up to 500 plate throughput with integrated execution records and imaging checkpoints.

- Up to 500 plate runs

- Structured batch records

- Deployment at density (1 m × 1 m)

Plan the dALI 500 deployment

dALI 500 is the manufacturing-scale member of the dALI family. If you are planning a scale-up path from R&D to manufacturing, we can map your protocol and throughput targets to an automation roadmap.

Need research-scale first? Explore dALI 24 →